Welcome to RIDILUX LIGHTING

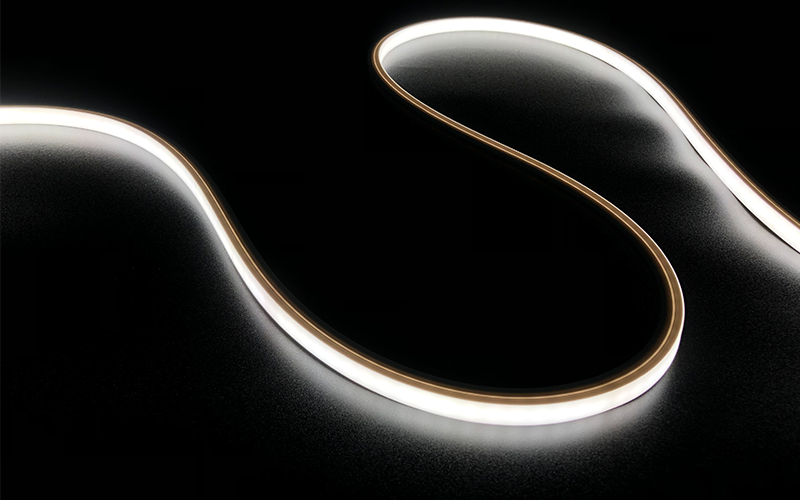

Commercial Flex vs Engineering Flex — Two Paths of Flexible Wall Washer

Two Paths of Flexible Wall Washers — and Why Only One Belongs to Architecture

The flexible wall washer market is split into two paths: Commercial Flex and Engineering Flex.

Both exist for different purposes — but 90% of project failures come from choosing the wrong path.

Traditional rigid wall washers failed because they forced architecture to compromise.

Flexible wall washers were meant to solve that — but only when they are built for architecture, not for decoration.

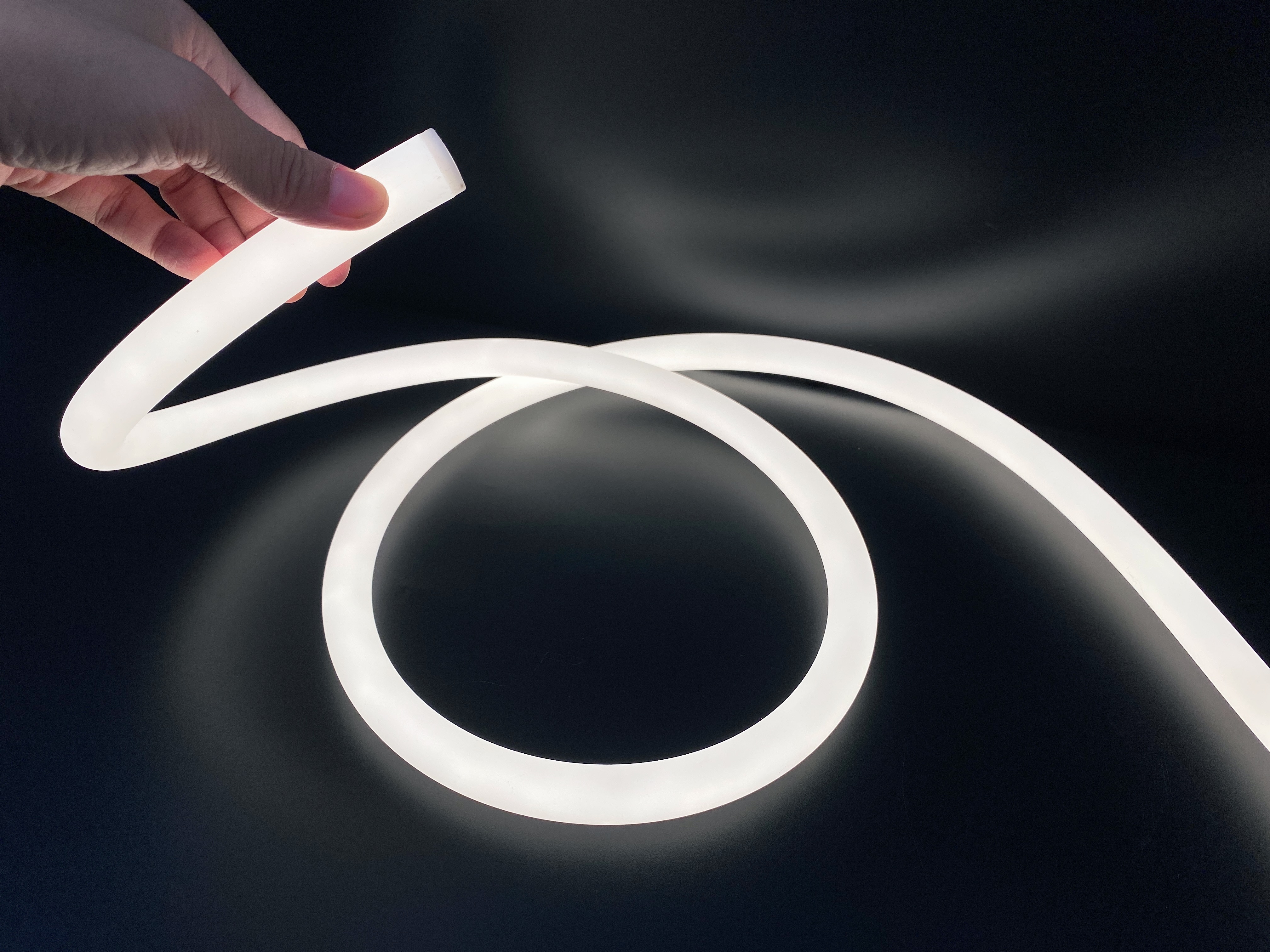

01 · Commercial Flex — “Can Be Used”

Commercial Flex is designed for circulation and cost efficiency, not architectural responsibility:

2–3 year warranty

Lightweight structure

Lower wattage

Limited beam options

Minimal anti-glare capability

Best for:

Decorative lines, small façades, indoor use, or non-critical scenarios.

Commercial Flex is not “wrong.”

It is simply not engineered for responsibility.It is lighting you can use — not lighting you can trust.

02 · Engineering Flex — “Built for Architecture”

Engineering Flex is a completely different discipline — built for serious façades and long-life outdoor conditions:

Aluminum heat-sink modules → higher wattage (15–48W) & longer lifespan

Optics from 12° upward → precise wall-washing control

Seamless continuity → zero visual breaks

Full outdoor certifications: IP67 / UV / Salt Spray / IK / High & Low Temperature

3-year standard warranty, extendable to 5 years

Multiple anti-glare systems

(lens / louver / shield / visor accessories)Customization options:

brackets, shields, angles, lumen levels, LED brand (up to 95 lm/W)

This is not “flexible neon with higher specs.”

This is an engineering-grade façade lighting tool.

02.5 · Why Most Flexible Products Fail Outdoors

(An Industry Mindset Problem)

The biggest issue in today’s flexible lighting market is not craftsmanship — it’s mindset.

Most neon and strip manufacturers originate from LED trading or component selling.

They operate with a commodity mindset:

Fast production

Low cost

“Good enough to light up”

But outdoor façades are architectural environments, not inventory destinations.

Engineering-grade products must prioritize:

Environmental adaptation

Long-term reliability

Outdoor protection

Thermal control

Optical consistency

—not circulation speed.

Our DNA is fundamentally different:

Founder from landscape luminaire engineering

Core co-founder from neon flex with design background

Team trained in industrial lighting disciplines

(thermal management, lifetime, reliability)Plus flexible supply-chain know-how for true customization

They sell strip lights.

We deliver architectural lighting tools.

03 · Market Matrix — We Provide Both, but Lead One

We offer both Commercial Flex and Engineering Flex —

but we lead with Engineering Flex.

Because façades deserve reliability, not improvisation.

04 · Why This Matters

Lighting is not installed for the day it is switched on —

but for the years that follow.

Wrong category = future maintenance risk

Right category = architectural integrity

05 · Closing

Flexible is not a shape.

Flexible is a standard.

Only Engineering Flex can carry that standard for real architecture.

If you want full spec sheets, engineering samples, or optical support for upcoming façade projects, feel free to DM us.