Welcome to RIDILUX LIGHTING

How to Choose LED Neon Flex for Swimming Pools | A Professional Guide

- LED neon flex

- Swimming pool LED lighting

- Waterproof neon flex

- Chemical resistance LED neon

- Pool lighting design

- Installation risk mitigation

Swimming pool lighting is one of the toughest lighting environments due to water immersion,

chlorine/salt exposure, heat cycles, and 24/7 operation. Standard outdoor LED neon products

often fail when applied underwater or near water lines. This guide explains the key technical

and practical criteria for selecting LED neon flex that truly performs in swimming pool

applications.

1. Understand the Environmental Challenges

A swimming pool imposes multiple stresses that ordinary outdoor neon cannot handle:

Constant contact with water

Chlorine/salt accelerated aging

Thermal expansion and contraction

UV exposure above water

Chemical plus mechanical stress

Most failures are not from a single cause — they’re compounded by the environment.

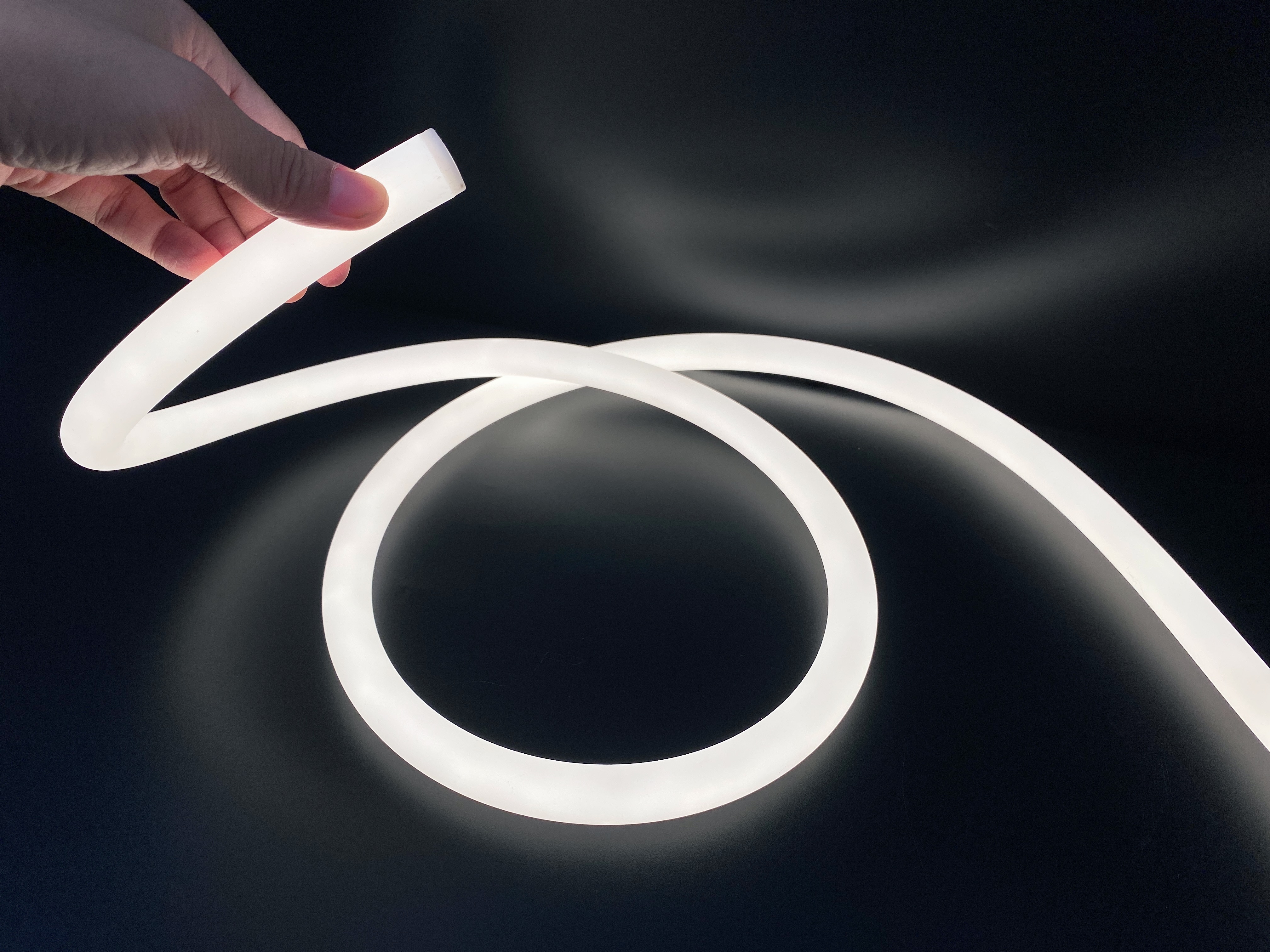

2. Waterproof Is Not Just an IP Rating

Many products claim IP68, but pool use is very different from brief submersion tests:

Look for full encapsulation (solid fill), not hollow tubes with end caps.

True pool-grade products are designed for long-term immersion, not short spray tests.

Check if the manufacturer provides real aging and immersion test reports.

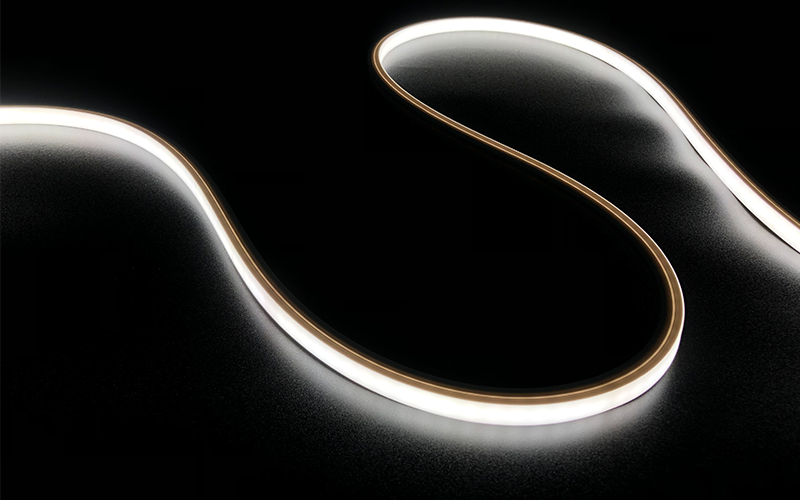

3. Choose the Right Silicone Material

Silicone quality determines long-term reliability:

Features to require:

High chemical resistance (chlorine/salt)

UV stability (anti-yellowing)

Elasticity over temperature swings

Non-brittle with long-term immersion

Low-grade silicone dries and cracks over time — it ages faster than the LEDs fail.

4. Voltage Strategy Matters

Swimming pools demand stable, even light:

Constant voltage neon

Simpler

Cheaper

Voltage drop over long runs

Constant power neon

Stable brightness from end-to-end

Ideal for long continuous pool outlines

Reduces overheating and mismatch

For uninterrupted pool perimeter lighting, constant power is recommended.

5. Minimize Joints & Connection Points

Every joint underwater is a potential leak point.

Best practices:

Plan lengths during design phase

Use as long continuous sections as possible

Place connectors above water line only

Avoid cuts near water

Well-designed installation can cut failure risk more than any sealant.

6. Heat, Chemistry & Aging

LEDs and silicones age faster in warm chlorinated water.

Ask suppliers:

Do they provide chemical aging data?

Has product been tested in chlorinated environments?

What is the lifespan projection under pool-like conditions?

If the supplier avoids technical answers, treat with caution.

7. Installation Considerations

Choosing product is step one — installation is step two.

Good design considers:

Drainage paths near neon

Mechanical fixes vs glue only

Expansion allowances at corners

Maintenance access

A lighting product becomes reliable only when matched with proper installation design.

8. Final Pre-Purchase Checklist

Before signing off on a product:

✔ Has this product been used in real swim pool projects?

✔ Can the supplier provide immersion lifetime data?

✔ Is silicone and sealing fully tested?

✔ Is power strategy defined for long runs?

✔ Are all joints above water?

If any is unclear → rethink selection.

Conclusion

Swimming pool LED neon lighting is a specialized engineered solution, not decorative lighting.

Choosing the right product protects the project reputation and reduces future maintenance

costs. Invest in proper materials, technology, and design — and the lighting performs for

years, not months.